Cherry, plum processing

Magnetic depalletizer:

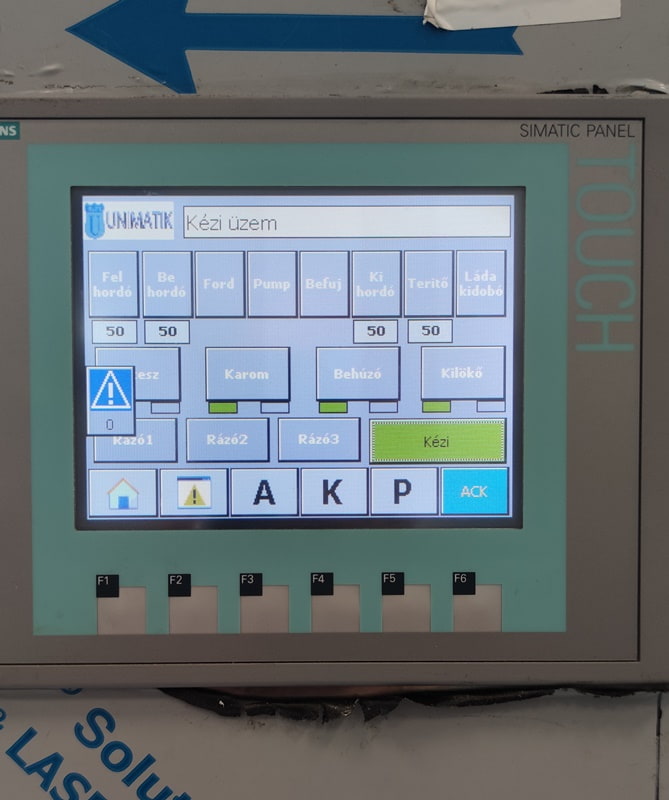

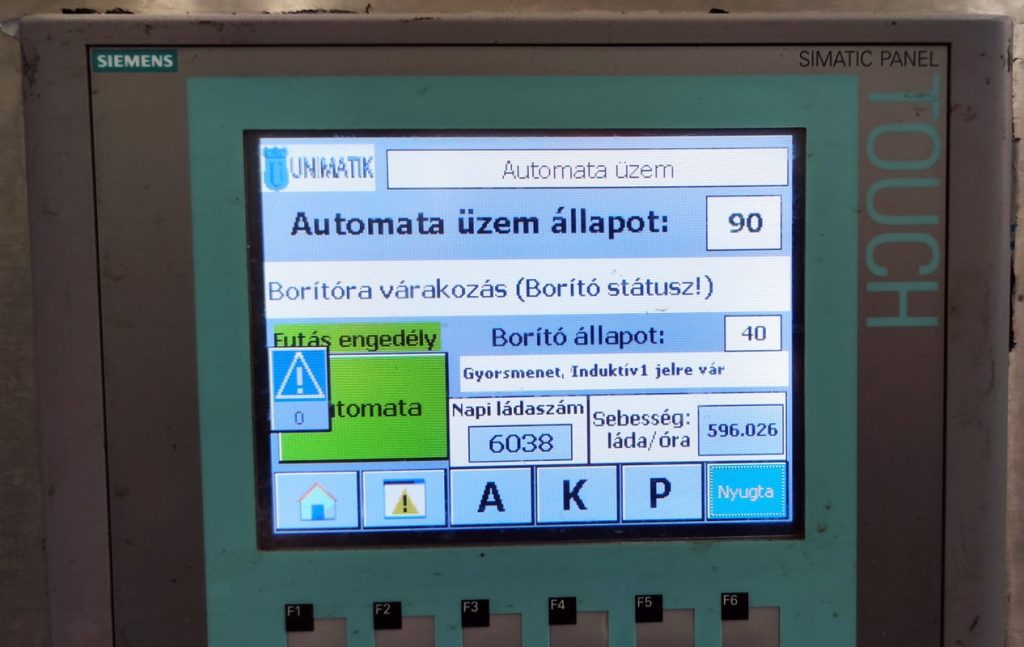

The depalletizer is located in front of the technological line, where it is placed. The depalletizing machine breaks down the unit load of the filled cylindrical containers and places them on a buffer table. The metal box is placed on the buffer table by a magnetic head. The frame of the depalletizing buffer table is made of bent stainless steel sheet with plastic tape. The frame structure of the magnetic head is also made of stainless steel, on which the carriage moves the magnetic head. The magnetic head is moved up and down by a pneumatic cylinder. We solve the lifting and lowering of the pallet with a chain hoist. The empty pallet is picked up by a roller track and collected separately. The equipment can handle pallets of different sizes. The machine is completely made of stainless steel. The machine can work in both automatic and manual mode. The machine is equipped with a PLC automation controller.

Magnetic palletizer:

The Palletizer forms a unit load from filled cylindrical containers. The metal box and the closed bottle are placed by a magnetic head from the buffer table onto the pallet. The machine places a paper and spacer between the layers manually or automatically. The frame of the stop table of the palletizing machine is made of bent stainless steel with a strap with plastic members. The frame structure of the magnetic head is made of stainless closed section and bent U-iron, with a magnetic head moving carriage. The magnetic head is moved up and down by a pneumatic cylinder. The pallet is raised and lowered with a chain hoist. The finished unit load is removed from under the magnetic head by a roller track. The machine is completely made of stainless steel. The machine can work in both automatic and manual mode. The machine is equipped with a PLC automation controller.

Glass and box depalletizer:

The depalletizer is located in front of the technological line, there. The equipment is made of stainless steel. The machine pushes the goods from the pallet onto the buffer table. The frame of the depalletizing buffer table is made of bent stainless steel sheet with plastic tape. We solve the lifting and lowering of the pallet with a chain hoist. The empty pallet is picked up by a roller track and collected separately. The equipment can handle pallets of different sizes. The machine is also suitable for removing boxes and bottles from pallets. The machine can work in both automatic and manual mode. The machine is equipped with a PLC automation controller.

Automatic compartment emptying machine:

Automatic compartment emptying machines play a very important role in technological processing in the food industry, but especially in the refrigeration and canning industries. By putting the compartment emptyer machine into operation, heavy manual work can be reduced, especially when processing bulky products. The task of the machine is to empty the solid vegetables and fruits to be processed from the compartments. The pallets with the compartments must be placed on the roller track with a forklift, which will automatically take them to the elevator equipment. The elevator structure lifts the pallet, then the tweezers take off four compartments and place them on the roller track above, which are forwarded to the two emptyer units. When the pallet is empty, the roller track takes it to the pallet collector, and then the cycle repeats. The equipment ejects the empty compartments to the side. The equipment is made of stainless steel. The machine has a PLC automatic control unit.

The equipment can be connected to the compartment washing equipment for cleaning empty compartments.

Semi-automatic comparment emptyer machine:

Semi-automatic compartment emptyer machines play a very important role in technological processing in the food industry, but especially in the refrigeration and canning industry. By putting the comparment emptyer machines into operation, heavy manual work can be reduced, especially when processing bulky products. The task of the machine is to empty the solid vegetables and fruits to be processed from the compartments. The compartments are placed manually on the elevator belt. The belt then carries it up to the comparment emptyer unit, which automatically empties the comparment and ejects the empty magazine to the side. The performance of the machine depends on the time required to load the compartments. The equipment is made of stainless steel. The machine has a PLC automatic control unit.

The equipment can be connected to the compartment washing equipment for cleaning empty compartments.

Calibration of cherry:

The task of the machine is to classify counties of different sizes. The machine is usually designed for two sizes of cherries. The smaller fruit falls into the rotating drum of the machine and is carried away by a conveyor belt. The larger size falls out at the end of the machine onto the next technological machine.

Vibration table:

Vibration table a very important role in the technological processing of the food industry, but especially in the refrigeration and canning industry. Its task is to arrange the individuals of various vegetables and smaller fruit varieties in a solid state to be processed in a plane, in a uniform layer thickness, to the next machine and equipment of the technological processing line. allowance. Its special task may also be the separation of water from the raw material, – surface water reduction – and waste separation. If the vibrator is equipped with a water jet, in that case the removal of smaller dirt, with this function, it also performs the task of washing and cleaning well.

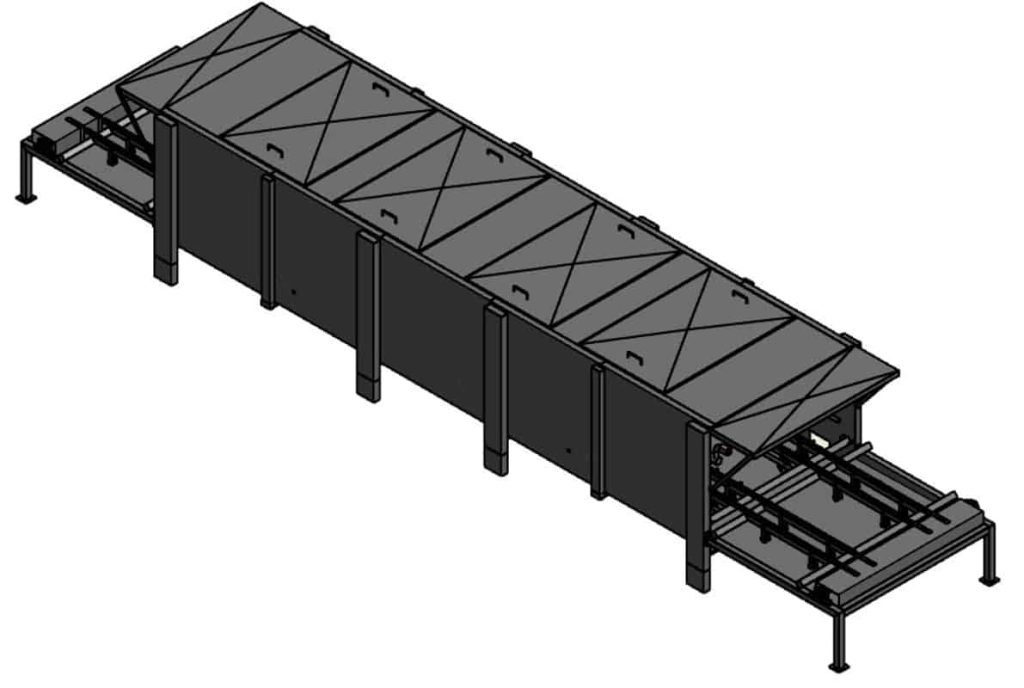

Alpa continuous spray pasteurizer:

The members of the PF type module spray pasteurizer family are suitable for pasteurizing goods packed in large bottles, bottles, and boxes below 95 C . Its operation is continuous. Pasteurization and cooling takes place in a spray system. Its performance varies widely depending on the size of the roll and the pasteurization time. The machine can be switched to the cooling mode and its independent pasteur modules make it suitable for multi-purpose use with optimal performance. The length of the machine must be at least 8 meters. The parts of the machine are the feeding buffer table and the three-track dispensing belt located at the end of the machine. The equipment is completely made of stainless steel. The machine is equipped with a PLC automatic controller, where the pasteurization time for the given product can be set and saved for later use.

Product transport machines

Auger sugar conveyor:

The sugar application auger is used in fruit and vegetable processing lines during the processing of juice, syrup, etc. to make the sugar syrup, add the sugar to the syrup cooking pot. The application auger is located on a transport trolley made of a closed section, so it is possible to supply several syrup cooking vessels with a sugar application. Two of the four wheels are self-aligning and two can be braked. It is made in stainless steel.

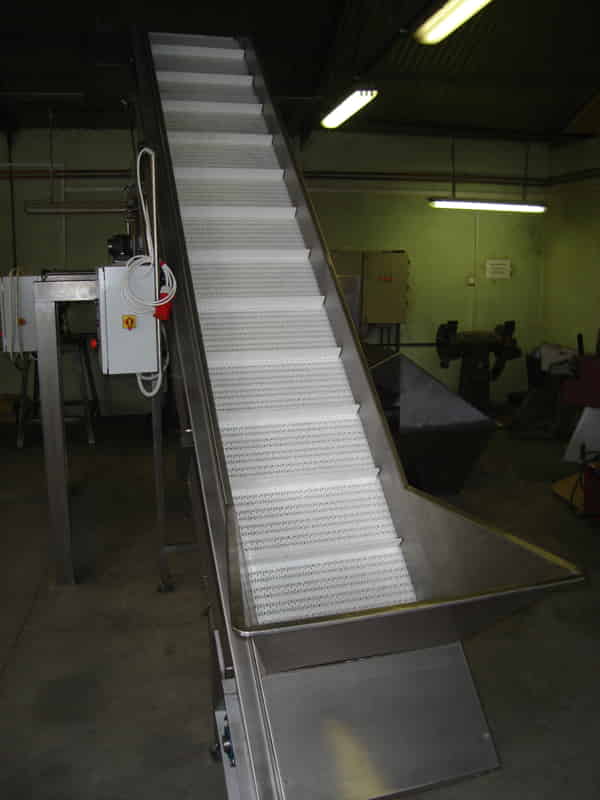

Bucket elevators:

Bucket elevator is to bridge the differences in height between the individual technological devices during the technological processing of the solid, different types of vegetables and fruits to be processed. In practice, this bridging means in almost all cases the transfer of the raw material or product to be processed from a lower technological level to a higher technological level. Bucket elevators can be installed anywhere in the technological production line. They can be made with a belt made of PVC or plastic and with a paddle.

Swan-neck elevator:

The task of the Swan-neck elevator is to bridge the height differences between the individual technological equipment during the technological processing of the solid, different types of vegetables and fruits to be processed. In almost all cases, this bridge means bringing the raw material to be processed, the product, from a better technological level to a higher technological level. Elevators can be installed anywhere in the technological production line. It is made with a belt with plastic members and a paddle.

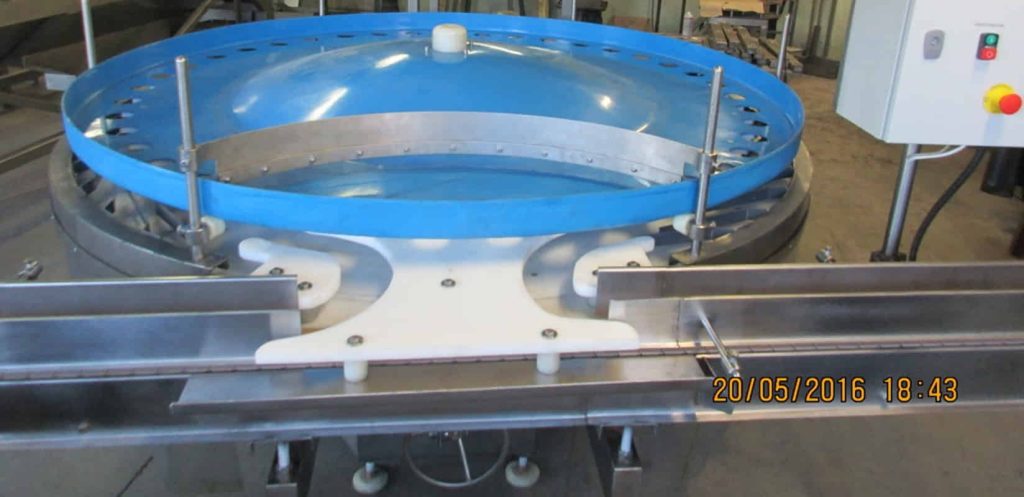

Puffer table:

The task of the buffer table is to continuously transport packaging materials of different sizes (canning bottles, metal cans, beverage bottles) in accordance with the requirements and regulations of the processing technology, and to collect them in front of various very important technological machines, so-called buffering. The collection and buffering is necessary so that the loss of production due to minor technical errors occurring at individual technological machines does not occur at the leading machines of the technological line, and ultimately the capacity utilization of the technological line is maximized. The buffer table is made with a belt with plastic members.

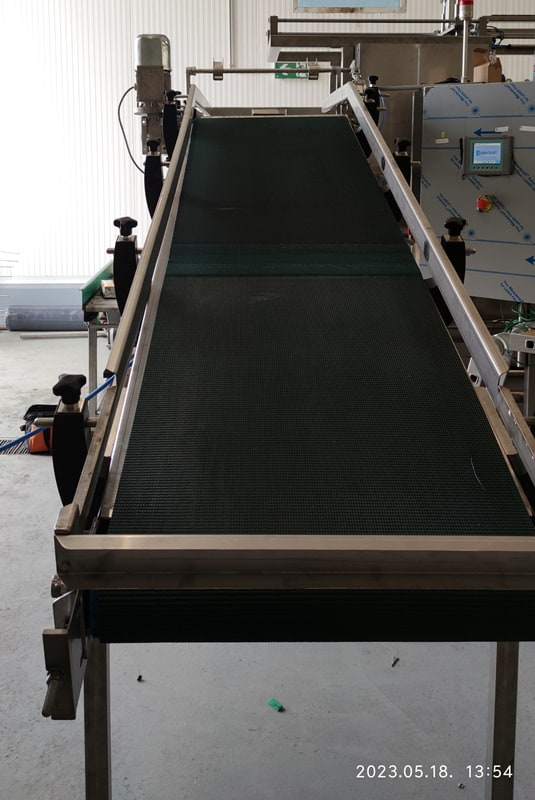

Conveyor belt machine:

Its task is to provide the opportunity to manually remove individuals from the solid state of different types of vegetables and fruits to be processed, as well as to transport the products from one technological machine to the next. Conveyor belts can be installed anywhere in the technological production line. The belt can be made of PVC or plastic.

Glass dispenser-applicator:

The task of the glass dispenser-sender is to transport empty or filled bottles and boxes, and to bridge level differences. The equipment transports the caught dishes at 90 degrees from one technological machine to the next technological machine. It is made of stainless steel.

Glass-Box Conveyor Track:

Continually operating glass, box and bottle conveyor tracks are the most common in the food industry, but especially in the canning, soft drinks, and beer industries. They are used to transport empty or filled jars, bottles and box. Its task is the continuous transport of packaging materials (glass, metal cans, plastic bottles) between the machines and equipment of the technological line. There can be straight and curved tracks. They can be of different widths and lengths. It can be single-track or multi-track.

Loss-free elevators:

Installed in the processing lines of canneries and refrigeration plants, the equipment is suitable for the loss-free delivery of various types of products. Its construction enables simple and safe handling, reliable long-term operation and minimal energy consumption. Its installation is simple, it can be easily connected to a production line. It is primarily suitable for transporting crushed corn, green peas and diced vegetables. It is made in stainless steel. Different sizes are produced.

Standing brush washing machine:

The equipment is made using stainless materials. There are 8 standing, rotating brushes in the machine body, which are used for cleaning. The product is carried out by an endless strapping made of plastic elements. Brush washing equipment is primarily useful for highly fragmented surfaces with a large adhesive surface, as well as for raw materials with difficult-to-remove impurities.

Metal Box steamer:

Spiral box steamer machines play a very important role in technological processing in the food industry, but especially in the canning industry. Their task is to examine the steaming and cleanliness of the various packaging boxes that enter the technological line before filling. The amount of steam required for steaming comes from the mains pressure technological steam system. Can be used for boxes of different sizes.

Compartment washer:

Compartment washing equipment plays a very important role in the technological processing of the food industry, but especially in the refrigeration, canning and meat industries, as well as in the distribution of large batches of raw goods. It is used for the complete removal of dirt on the outer/inner surface of the crate washing equipment. It can be used for compartments of different sizes.

Jar blowing and cleaning:

Spiral jar blowing and cleaning machines play a very important role in the technological processing of the food industry, especially the canning industry. Their task is to examine the pre-filling rinsing of various packaging bottles entering the technological line. The amount of water required for rinsing is taken from the technological water system using network pressure. It can be used for bottles of different sizes.

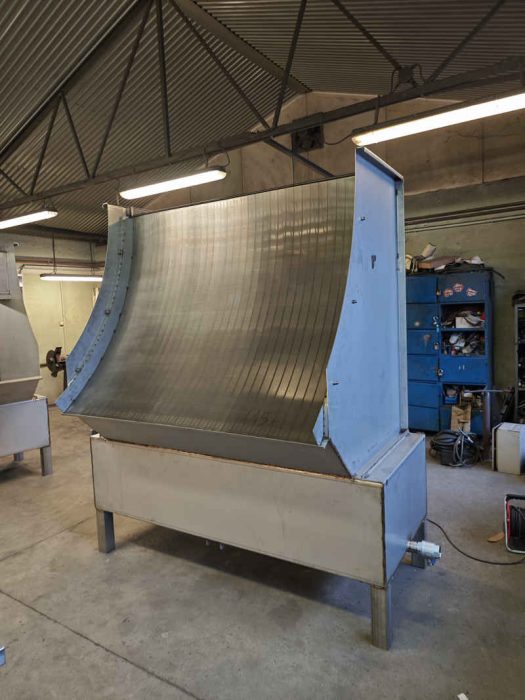

Bubbling washer machine:

The equipment consists of an acid-resistant welded tub, from which an endless belt made of plastic elements delivers the product. With air, which ensures the cleaning of the product and the bubbling of the water. The pump mounted on the conveyor belt ensures a more intensive progress of the product. It is used for washing fruits and vegetables with a softer surface.

Container washer:

The container washer plays a very important role in the food industry, especially in the technological processing of refrigeration, canning and meat processing, as well as in the distribution of bulk raw materials. Raw materials delivered for technological processing must be transported in containers. The container washing equipment is used for the complete removal of dirt on the outer/inner surface of the containers. Can be used for containers of different sizes.

Bock filling machine:

The machine is used for gentle filling of various fruits and vegetables (e.g. cucumbers, cherries, cherries, etc.) into bottles and boxes. The product is placed on the filling disc with a slide or a conveyor belt, the speed of rotation can be regulated with a stepless gear. The product to be filled falls through the openings of the filling disc into the bottles below. Special input and output sets take the bottles from the glass conveyor belt under the filling machine. An inlet and outlet set is required according to the glass size. Filling the raw materials into the bottles requires manual effort.

Herbort filling machine:

The task of the Herbort filling machine is to place and fill the solid state of different types of vegetables and fruits to be processed into packaging material (glass, box). The machine is in continuous operation. During filling, the raw material enters the packaging material without the use of manual force, by machine. The filling machine is made of four main units: feeder, filling part, transporter and returner. The equipment is made of stainless steel.

Liquid filling machine:

Continuously operating liquid filling machines a very important role in technological processing in the food industry, but especially in the canning industry. Its task is to provide the appropriate amount of juice for the various vegetables and fruits to be processed, after placing them in the packaging material (glass, box). The filling of the filling juice and delivery to the packaging material is done by gravity, which is why the name „gravity” draining is also common in professional circles. From above, evenly, on a layer of film, draining pouring juice flows into the packaging material passing below until it is full. The extra juice is returned to the processing and pouring juice system for reuse. The machine is made of high-quality stainless steel.

Filler of vibrating:

The task of the vibration filling machine is to place and fill different types of vegetables and fruits in a solid state to be processed into packaging material (glass, box). The machine is in continuous operation. During filling, the raw material enters the packaging material without the use of manual force, by machine. The filling machine is made of four main units: feeder, filling part, transporter and returner. The equipment is made of stainless steel.

Volume filler machine:

Volume filling machine: The machine is suitable for filling hard, half-piece products / peas, corn, corn, etc./ into boxes or bottles. The frame structure of the machine is made of stainless acid-resistant material, which contains all the drive units:

– wheel unit;

– charging and dispensing plates; upper plate, which regulates the amount of product with the help of telescopes and flywheels; the top plate is fixed on a wheel.

– lead and lead star.

The conveyor belt built on top of the table conveys the product to the dosing auger, which has a variable classification to facilitate the easier feeding of the boxes. The product is placed on the upper plate, which is placed above the boxes, or in the filling cylinder, and a vibrator or applicator fills the product into the device to be filled. The two filling plates move on the axis and open during the filling stage, ensuring that the product is filled into the boxes. In the filling section, an automatic plate is installed, which is connected to a driver and only allows charging when there is a device to be charged under the charging head. A vibrator is placed above the boxes, which ensures even filling of the product. The machine is made with different numbers of heads: 28-44-48-52-60, depending on the power of the machine. The machine is made with PLC automatic control.

Magnetic cap feeders:

The magnetic cap feeders automatically transfers the cap towards the capping machine. The cap is brought from the container to the chute by a magnetic belt, through which the cap is transferred to the capping machine. The equipment is completely acid-proof, except for the gear unit. The cap feeder is automatic and its speed is adjustable.

Heatable mixing tank:

The mixing, heatable tank is used for mixing and heating various food industry liquids and mixing in additives. The mixer tank is a cylindrical vessel with a vertical axis standing on three tubular legs, with a mixer directly driven by an electric motor on top. The cylindrical shell of the vessel is stiffened by a semi-flat sheet lid on top, and the bottom is closed by a shallowly convex vessel bottom. The electric motor that rotates the mixer is located on the flanged, stiffened flat cover. The other half of the container is closed by an open lid, which facilitates the handling and cleaning of the container. The vessel is surrounded by a heating jacket on the outside, so steam heating enables the materials in the vessel to be heated. Hot surfaces are covered with thermal insulation. The tank has the technologically necessary stubs. A propeller mixer is built into the vessel for mixing materials in the vessel. The entire equipment (with the exception of the electric motor and gear unit) is made of stainless, acid-resistant steel.

Agitator tank:

An agitator tank is used to mix, heat and add additives to various food industry liquids. The mixing tank is a cylindrical vessel with a vertical axis on three tubular legs, topped with a stirrer directly driven by an electric motor. The cylindrical shell of the vessel is stiffened by a semi-flat sheet lid on top, and the bottom is closed by a shallow convex vessel bottom. The electric motor that rotates the mixer is located on the flanged, stiffened flat cover. The other half of the tank is closed by an open lid, which makes it easier to handle and clean the tank. The vessel is surrounded by a heating jacket on the outside, so steam heating enables the materials in the vessel to be heated. Hot surfaces are covered with thermal insulation. The tank has the technologically necessary stubs. A propeller stirrer is built into the vessel to mix the materials in the vessel. The entire equipment (with the exception of the electric motor and gear) is made of stainless, acid-resistant steel.

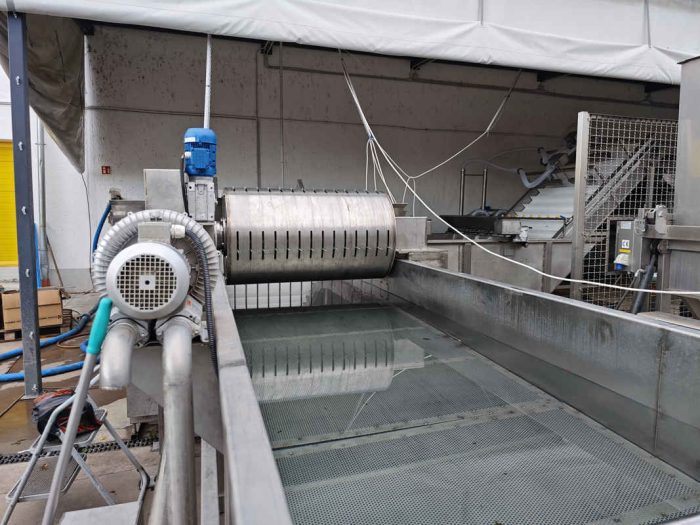

Leaf and twig removal equipment:

The unit is built towards a wash tub. Its function is to continuously remove the twigs and leaves floating in the tub when washing fruit and vegetables, and to place them on a conveyor belt that removes the debris.

The equipment is made in different sizes, depending on the size of the tub. It is made entirely of stainless steel.

Brewing station JF-04:

The equipment consists of two acid-resistant tanks (material KO-36 quality) located one above the other with three columns, an acid-resistant pipe snake (material KO-35) located inside, a pump, a mixer extending into the lower tank and necessary pipelines. The equipment is equipped with motor protection switches. The upper tank has temperature control, the tank is equipped with a dial thermometer and a juice filter is placed in the pressure branch of the pump.

TODAY

MESSAGE US

Fill out the form on our website today to start developing your food business and get ahead of the competition!

Address

4400 Nyíregyháza, Szélsõbokor 10/b