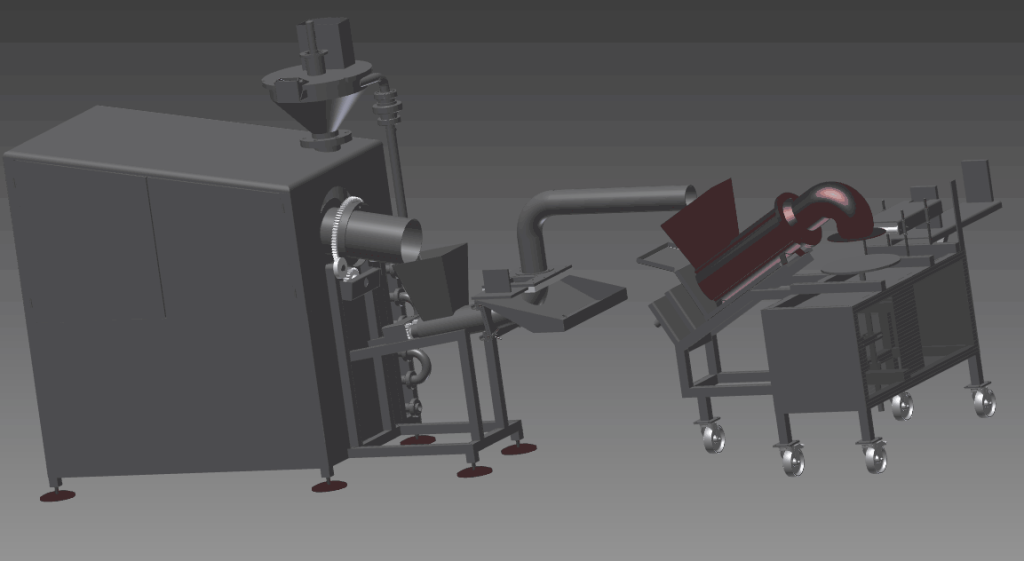

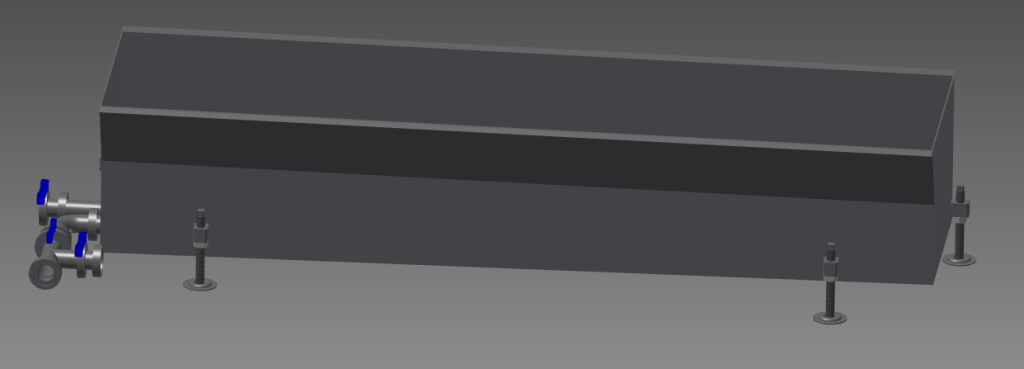

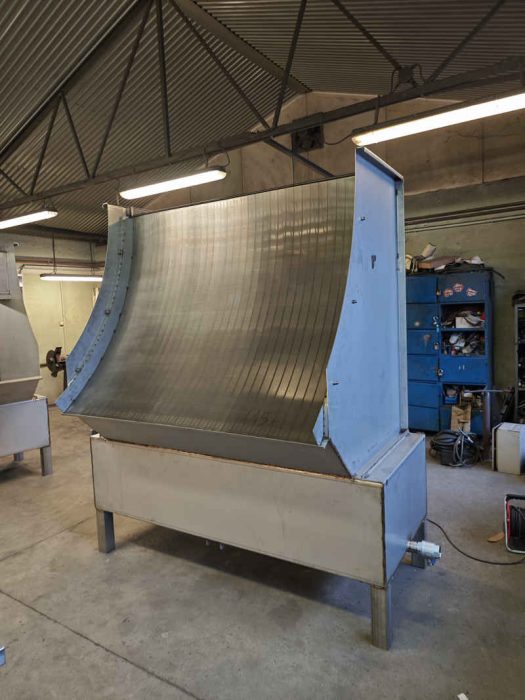

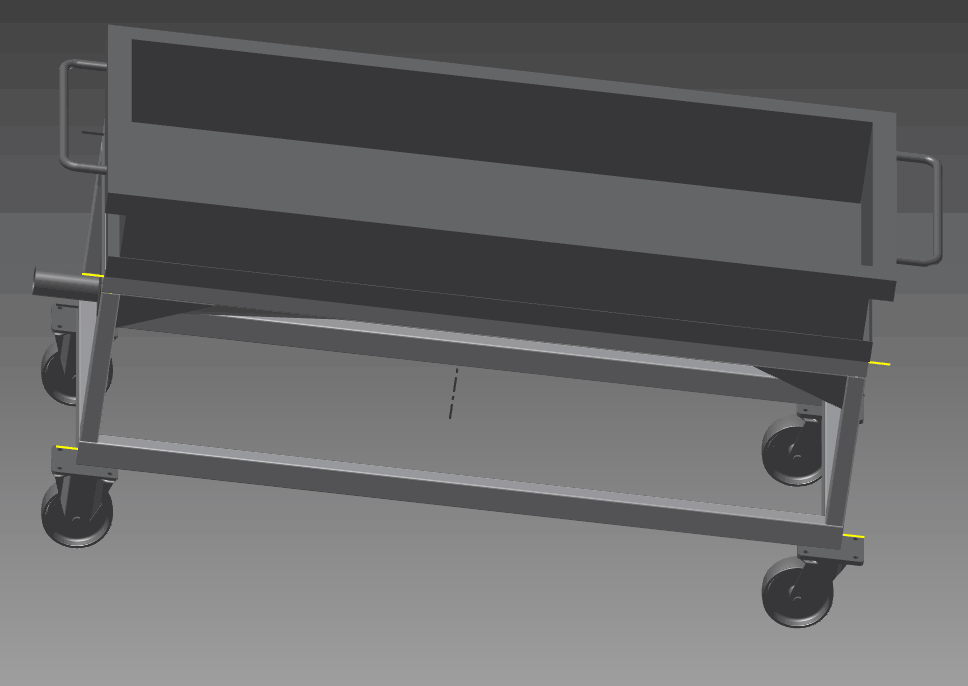

Conveyor belt machine:

Its task is to provide the opportunity to manually remove individuals from the solid state of different types of vegetables and fruits to be processed, as well as to transport the products from one technological machine to the next. Conveyor belts can be installed anywhere in the technological production line. The belt can be made of PVC or plastic.

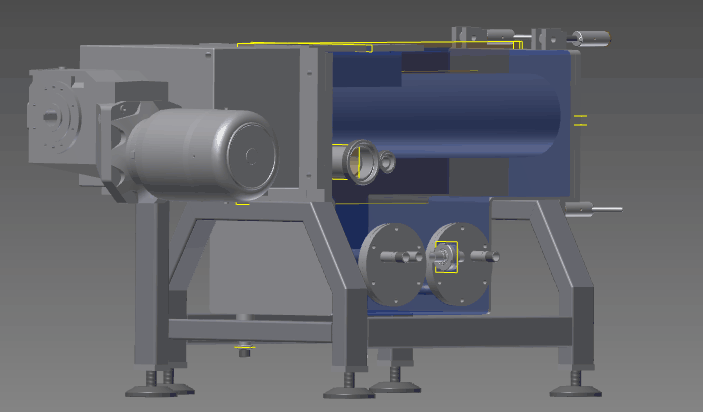

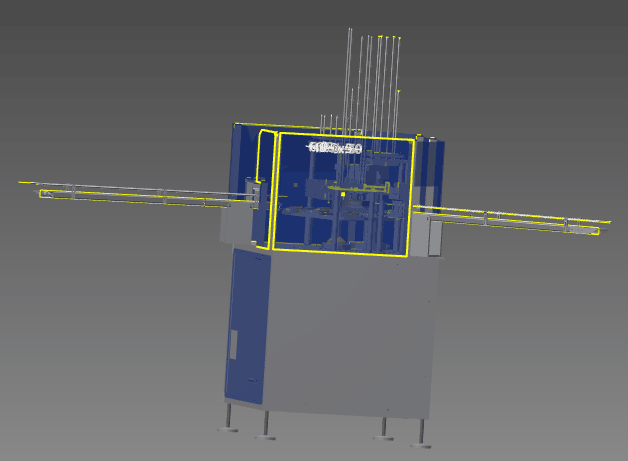

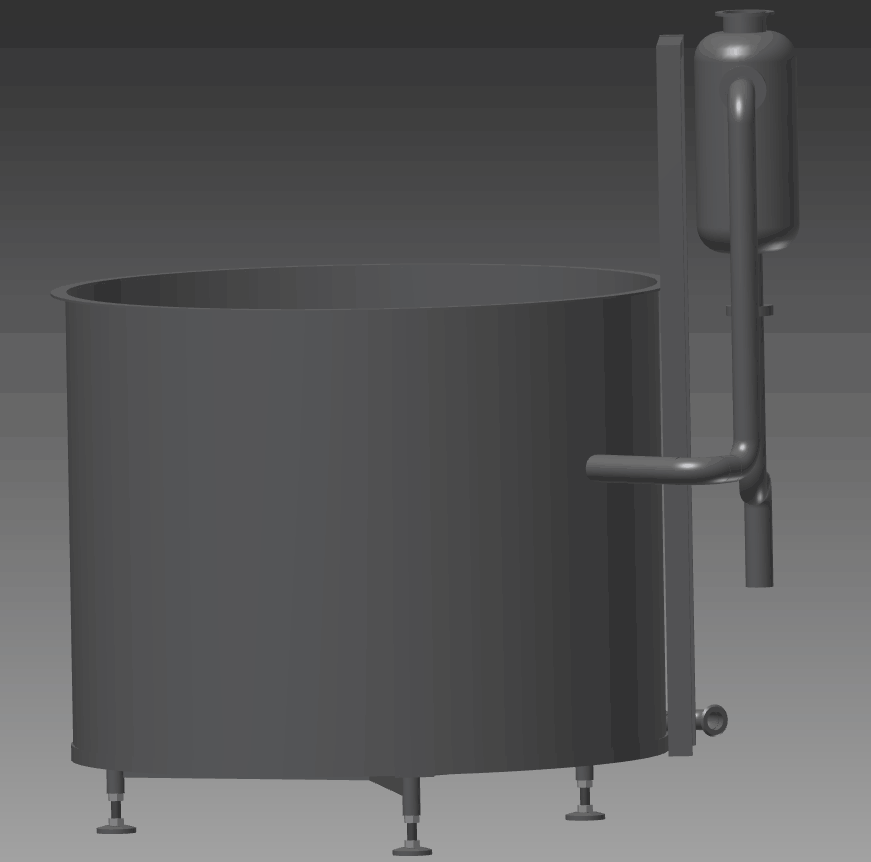

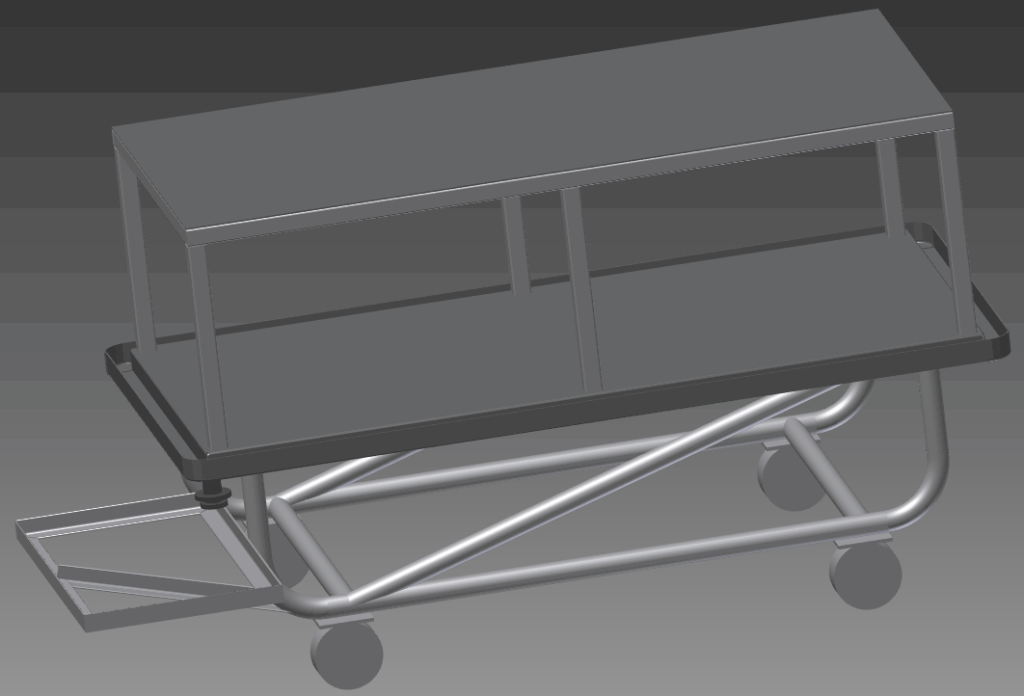

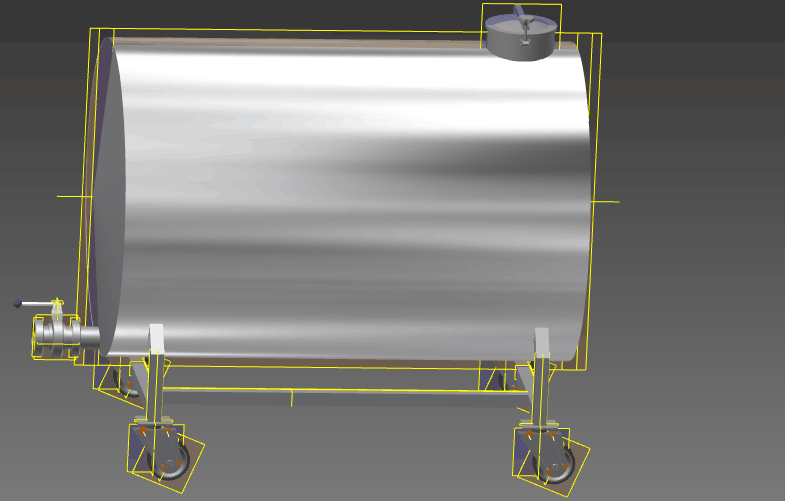

Heatable mixing tank:

The mixing, heatable tank is used for mixing and heating various food industry liquids and mixing in additives. The mixer tank is a cylindrical vessel with a vertical axis standing on three tubular legs, with a mixer directly driven by an electric motor on top. The cylindrical shell of the vessel is stiffened by a semi-flat sheet lid on top, and the bottom is closed by a shallowly convex vessel bottom. The electric motor that rotates the mixer is located on the flanged, stiffened flat cover. The other half of the container is closed by an open lid, which facilitates the handling and cleaning of the container. The vessel is surrounded by a heating jacket on the outside, so steam heating enables the materials in the vessel to be heated. Hot surfaces are covered with thermal insulation. The tank has the technologically necessary stubs. A propeller mixer is built into the vessel for mixing materials in the vessel. The entire equipment (with the exception of the electric motor and gear unit) is made of stainless, acid-resistant steel.

TODAY

MESSAGE US

Fill out the form on our website today to start developing your food business and get ahead of the competition!

Address

4400 Nyíregyháza, Szélsõbokor 10/b